True certification. Not just a label.

Most companies offer "inspections" with no reference to regulatory standards. We do it properly — certifying your vehicle hoists to AS1418.9:1996 | AS/NZS 2550.9:1996 as required by New Zealand law.

Our internal standards go further still, refined over almost three decades to reflect the latest developments in vehicle lifting. We regularly identify issues — sometimes serious ones — that others have missed entirely.

We've spent years developing and refining our processes, so our pricing remains competitive, and you still get the job done properly. Now that's a win-win!

Our inspections are comprehensive by design. We assess:

We don't skim. We don't rush.

This depth comes from genuine expertise. We understand hoist construction, tolerances, and failure modes intimately — and we've invested heavily in precision tooling and calibrated measuring equipment to match that understanding.

Beyond the minimum standard

Regulatory compliance is the baseline — not the finish line. Our processes allow us to note, record, and track inspection points well beyond base requirements. Over time, this creates a clear history of each machine: what's changing, what's stable, and what's approaching the point where action will be required. That foresight gives you control. Instead of reacting to failures, you can plan maintenance, manage risk, and avoid unnecessary downtime.

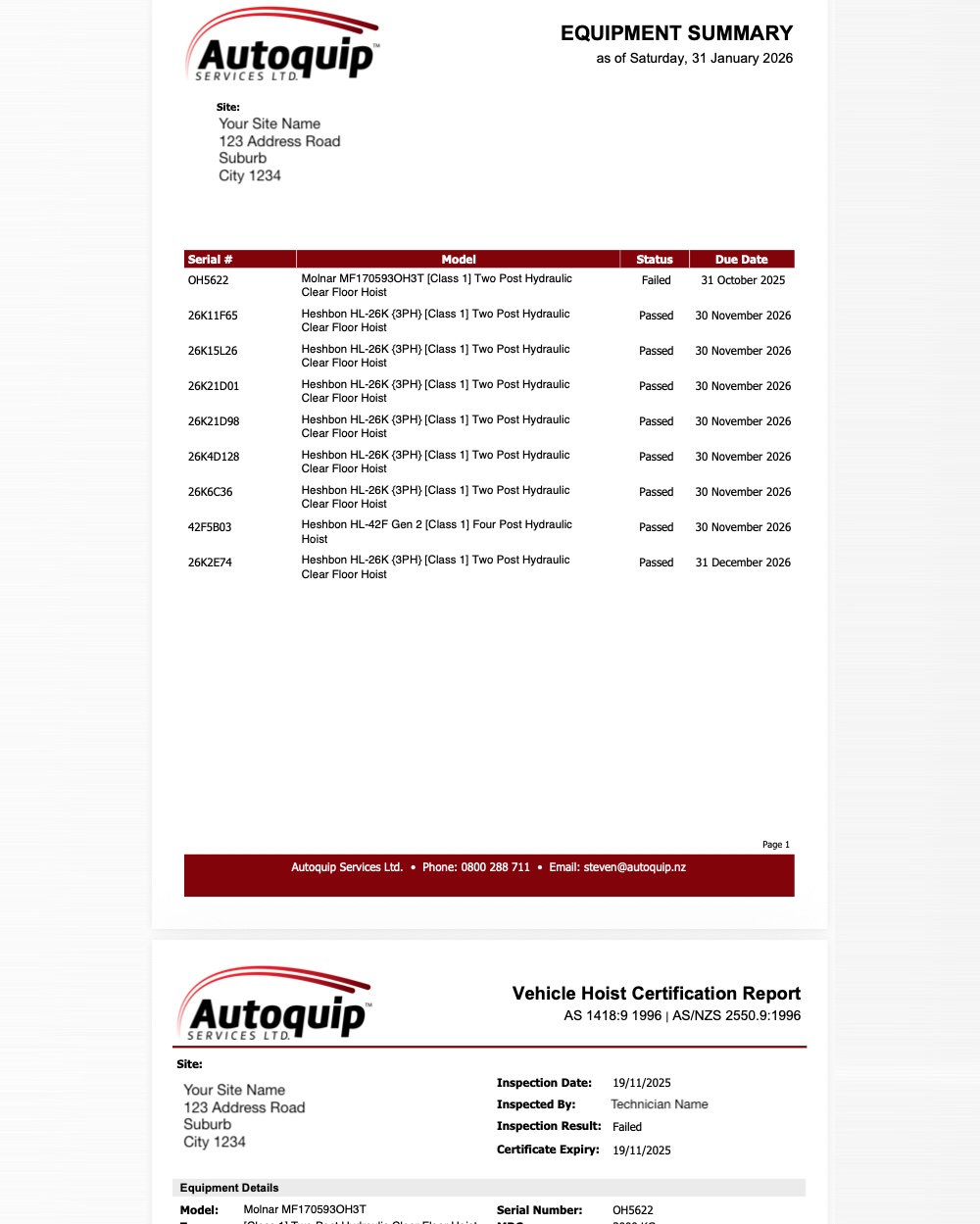

Every certification concludes with a professional PDF report, emailed the same day. You’ll receive a clear summary of all equipment on site, along with any issues, observations, or recommendations — documented properly and easy to reference later.

No chasing. No waiting. No loose ends.

Across almost thirty years of operation and multiple generations of equipment, our customers have nener experienced a death, serious injury, or vehicle loss attributable to equipment under our certification. That level of safety should be standard — and we treat it as such.

Beyond safety, the equipment we service regularly stands out for its long-term performance. We consistently see higher return on investment, longer mean time between failures (MTBF), and positive feedback from the technicians who use the machines day in, day out.

That record isn’t luck. It’s the result of conservative judgement, disciplined process, and a refusal to compromise on safety.

Your safety is our safety. Your business is our business.

Certification and servicing naturally belong on the same visit. The same technician, the same equipment, less disruption to your operation.

We offer a standard discount when both are carried out together — an efficiency that benefits everyone.

For more detail on our maintenance philosophy and low-disruption approach, see our Servicing page

Ready to book a certification done properly?

Talk to us early — especially if your compliance date is approaching. We'll tell you plainly what's required and when.

A glimpse of our certification work across the region.

These aren't stock photos or hypotheticals. These are real failures we've discovered during routine inspections — issues that could have caused serious injury or death if left undetected. This is why we inspect thoroughly, and why you should never skip certification.